By FORWELL

- Quick and easy die changing

- Very high clamping pressure

- High opening and closing speeds

- Easy insertion and removal

- Safer Operations

- Increased productivity

Die Clamp Introduction

All Forwell Quick Mold Change System use high quality Die Clamps for very secure clamping, quick mold changing and safer operations. These clamps can fasten Molds whether they are changed vertically or horizontally.

There are also a range of different Die Clamps available to suit your injection molding or mold casting requirements. The TY type Die Clamps are machined to fit into the T-slot of the bolster for extra secure positioning. The flange-mount model Die Clamps can be bolted onto the bolster and the automatic slider model Die Clamps makes remote automatic operation possible.

PRODUCT

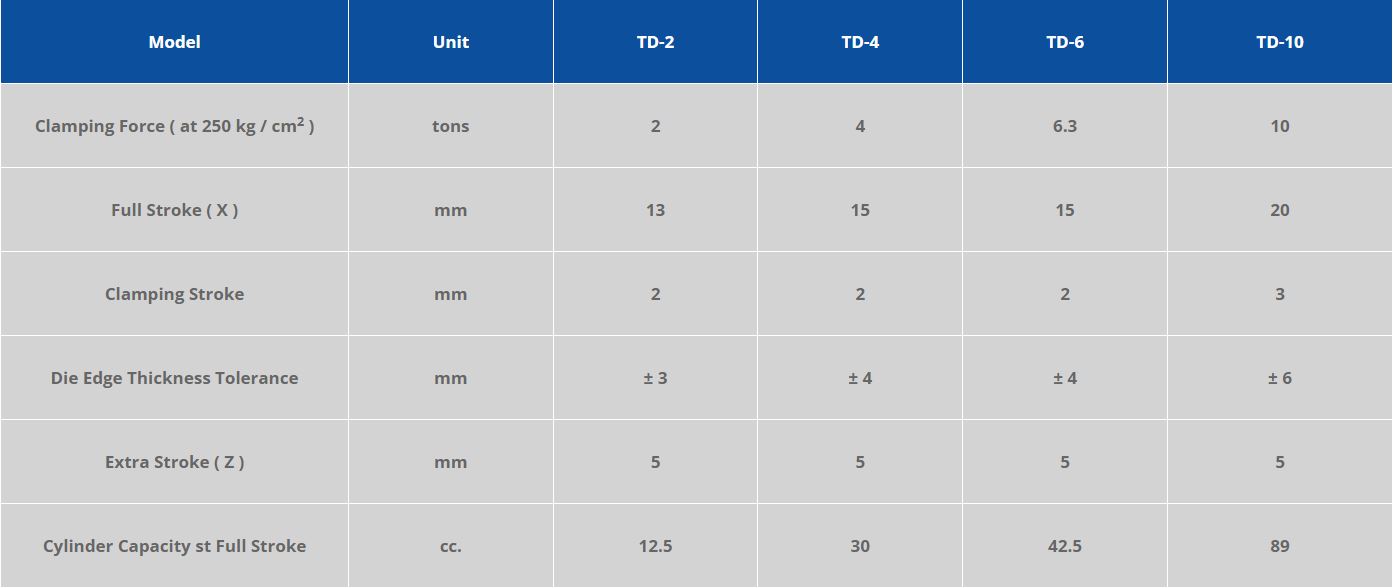

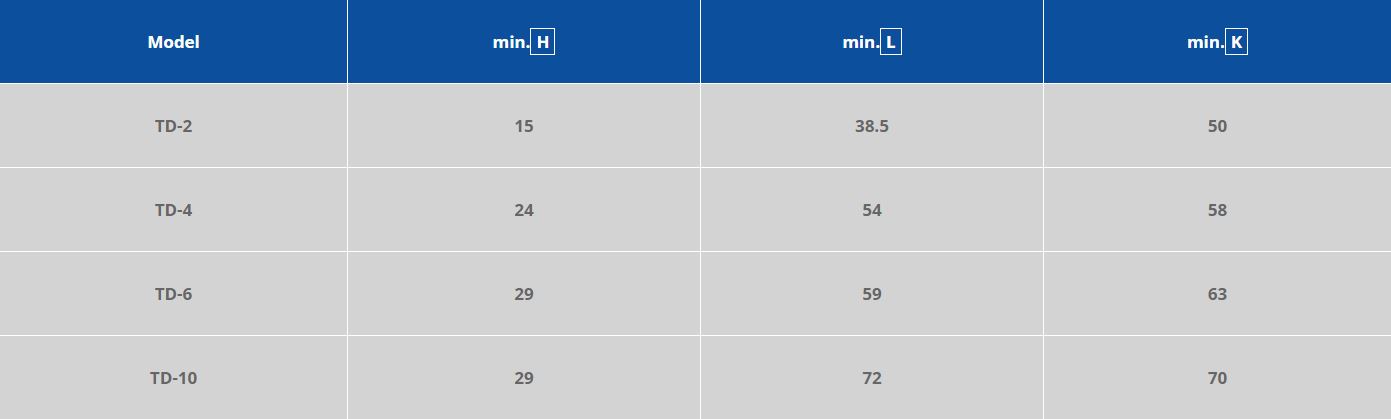

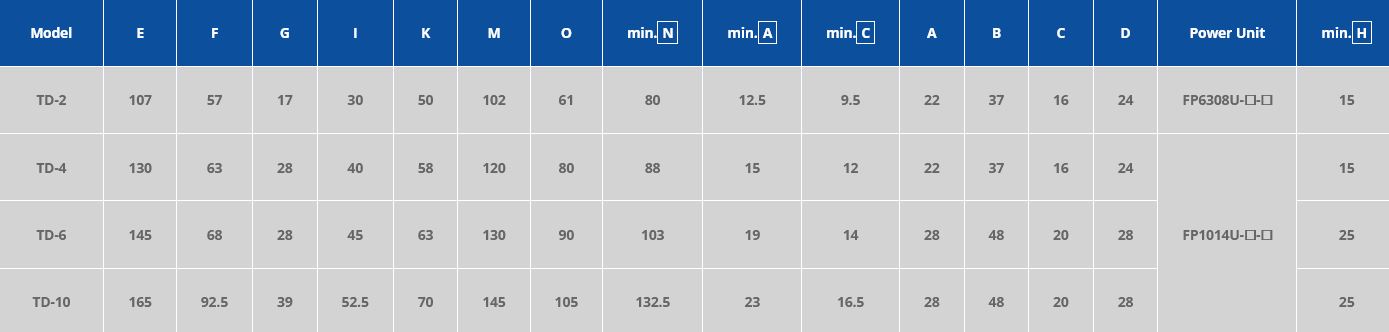

TD DIE CLAMP

This vertical type clamp does not required a U-slot on the die shoe.The clamping stroke will be longer.

specification:

* Extra stroke is the difference between full stroke and clamping stroke with extra space allowed for safe operation.

* Notice if "N" size is suitable for the die in closed condition.

* Notice Before purchase,please verify mold edge thickness (h) and T-slot(A.B.C.D) has standard or special dimensions.

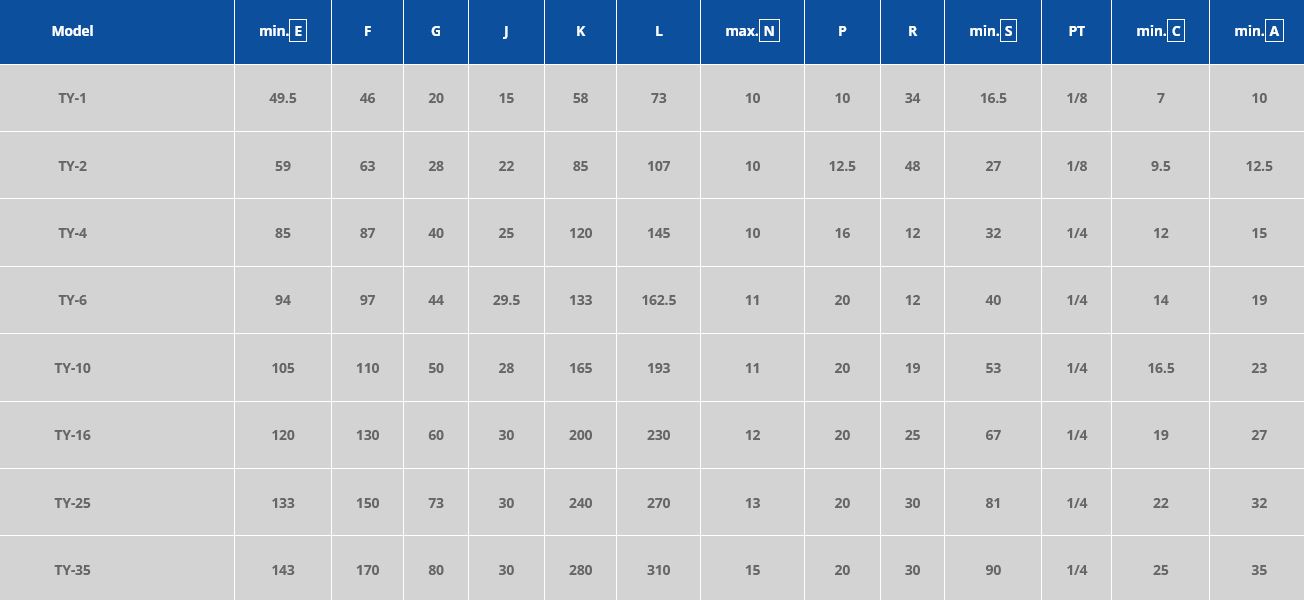

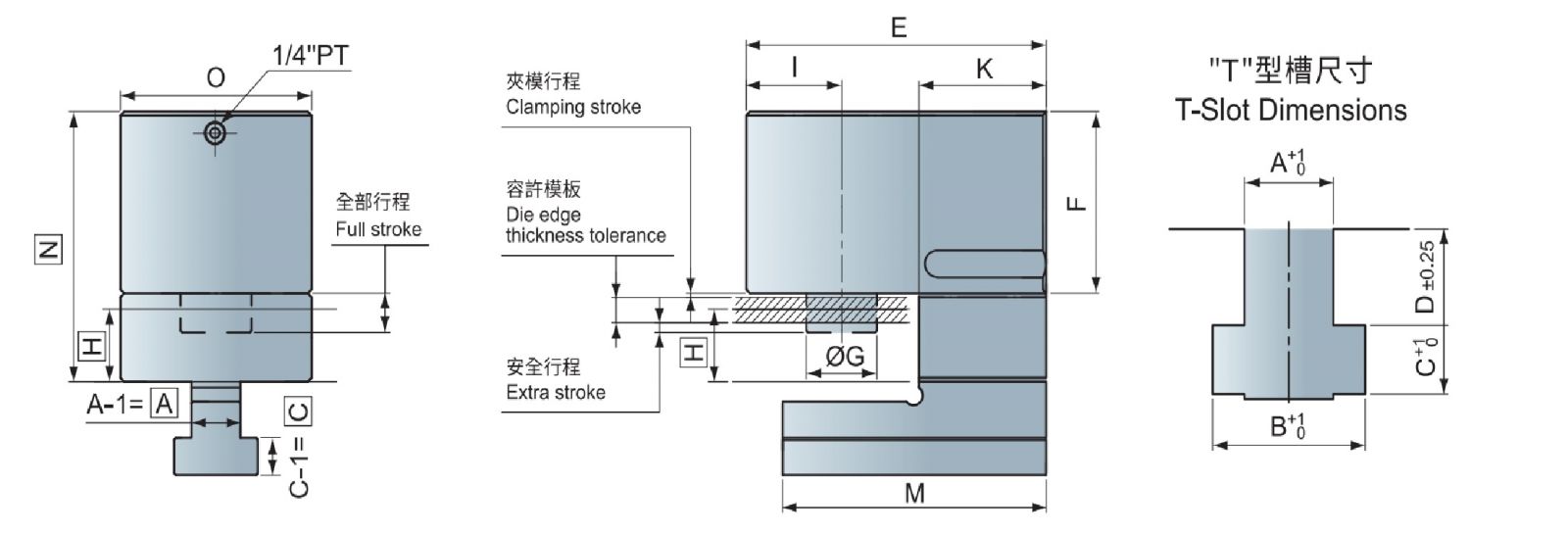

TY DIE CLAMP

- Quick and easy die changing

- Very high clamping pressure

- High opening and closing speeds

- Easy insertion and removal

- Safer Operations

- Increased productivity

As this lever-type clamp does not require a U-slot on the die shoe it can be used in a wide range of applications. The TY type Die Clamp are machined to fit into the T-slot of the bolster for extra secure positioning.The flange-mount model Die Clamp can be bolted onto the bolster and the automatic slider model Die Clamps makes remote automatic operation possible.

Die Clamp Introduction

All Forwell Quick Mold Change System use high quality Die Clamps for very secure clamping, quick mold changing and safer operations. These clamps can fasten Molds whether they are changed vertically or horizontally.

There are also a range of different Die Clamps available to suit your injection molding or mold casting requirements. The TY type Die Clamps are machined to fit into the T-slot of the bolster for extra secure positioning. The flange-mount model Die Clamps can be bolted onto the bolster and the automatic slider model Die Clamps makes remote automatic operation possible.

Clamps specification:

The following specifications can help you choose the appropriate clamp type in accordance with your injection molding requirements and production situation. Make sure of your production plans and production procedure before choosing your product to be sure of the product that best suits your needs.

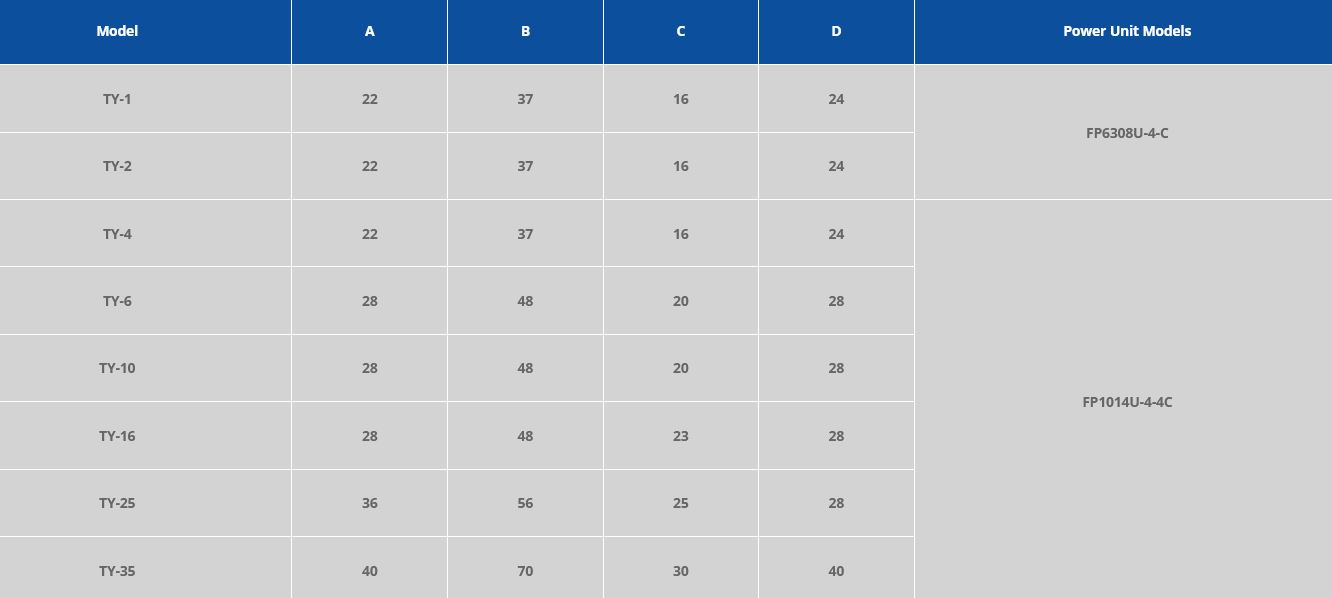

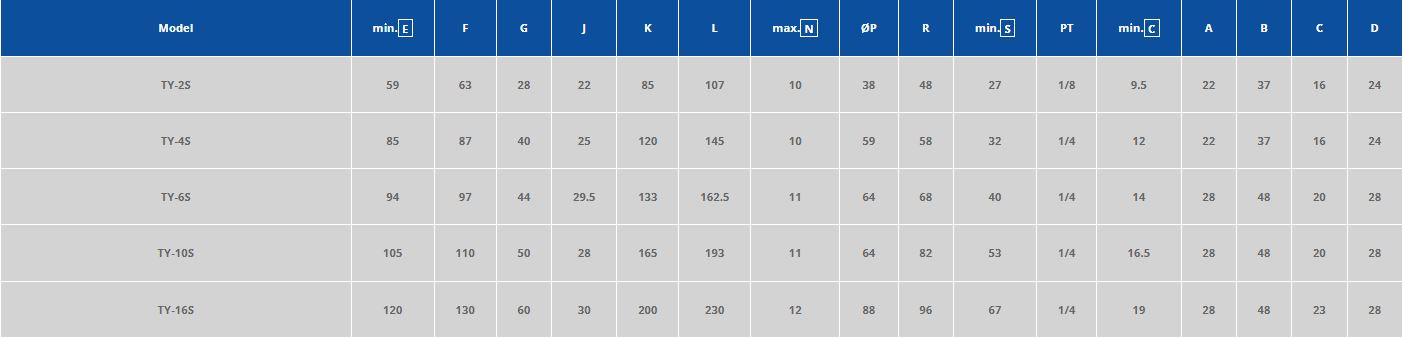

TY Clamp Model Specifications

Clamp Dimensions

For a closer look at the exact dimensions of the TY series die clamps please see the following diagram and table.

* Die shoe thickness (h) availabe : 25,30,35,40,45,50,55,60mm

* Before purchasing, please verify if the mold edge thickness (h) and T-slot (A.B.C.D) have standard or special dimensions.

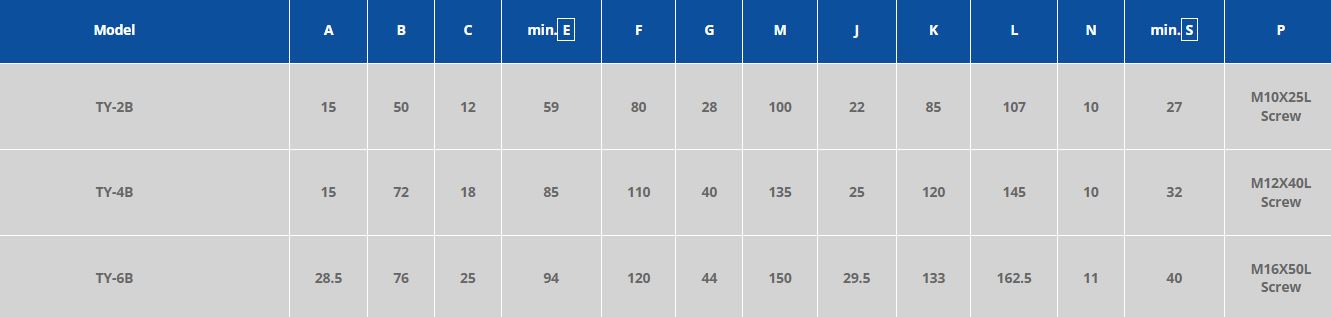

TY-B TYPE DIE CLAMP

Dimensions

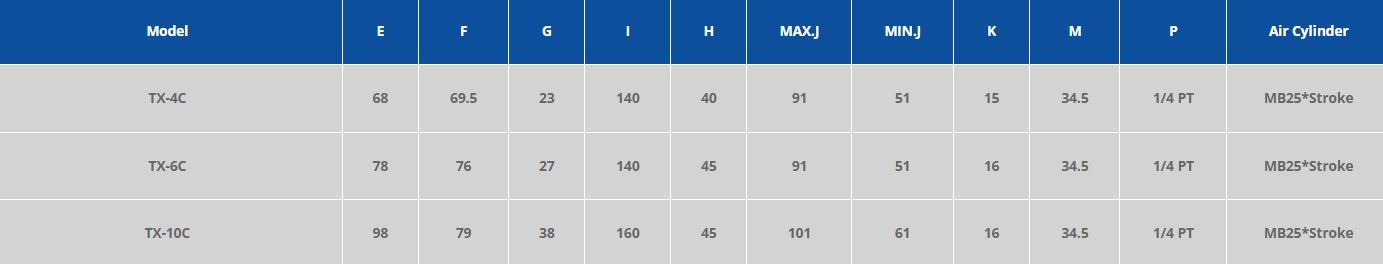

TX-C TYPE DIE CLAMP

Dimensions

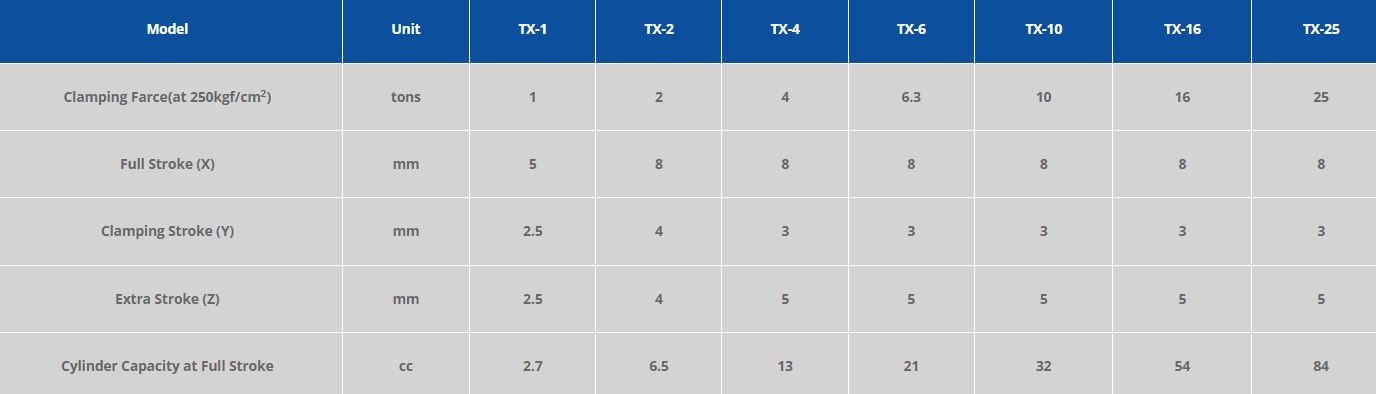

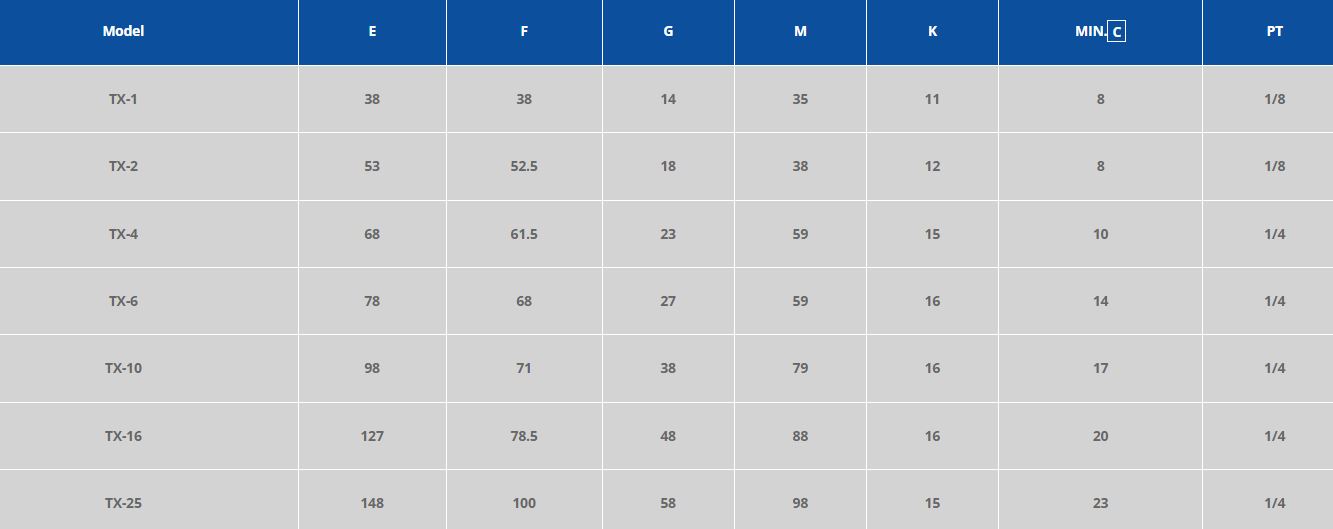

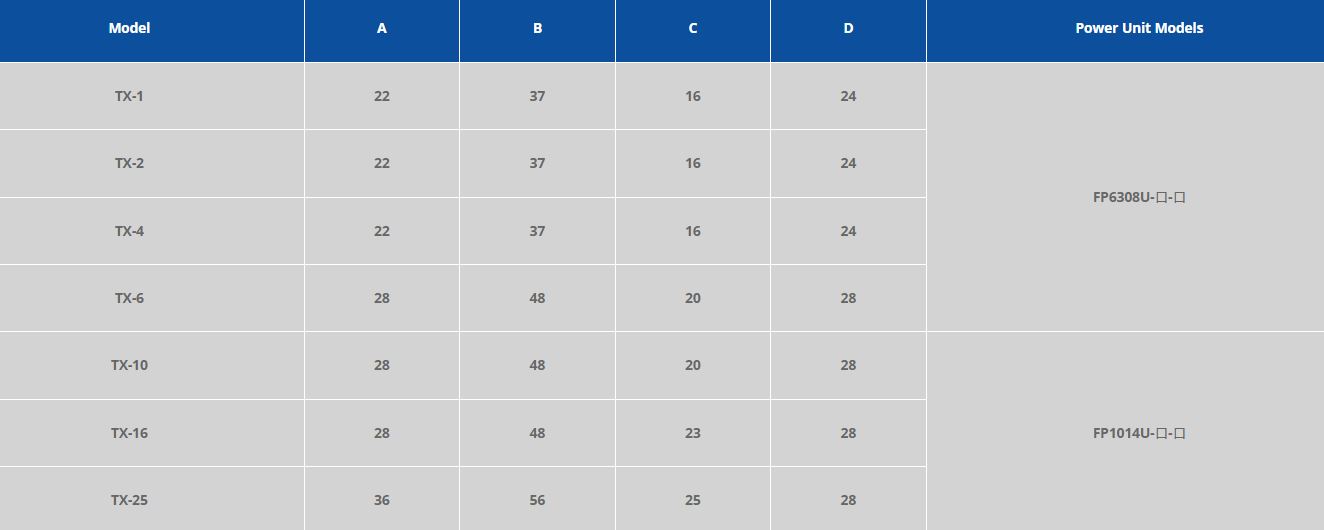

TX DIE CLAMP

This compact, space saving, piston type clamp requires U-slot on the die shoe. The clamp leg is machined to fit the T-slot on the bolster. With the TX Die Clamp automatic slide model remote control is made posibble.

specification:

* Extra stroke is the difference between full stroke and clamping stroke with extra space allowed for safe operation.

Clamp Dimensions

* Die shoe thickness(h) Classify : 25?30?35?40?45?50?55?60mm.

* Before purchase, please verify mold edge thickness (h) and T-slot (A.B.C.D.) has standard or special dimensions.

* Die shoe thickness(h) Classify : 25?30?35?40?45?50?55?60mm.

* Before purchase, please verify mold edge thickness (h) and T-slot (A.B.C.D.) has standard or special dimensions.

TY-BS DIE CLAMP

.png)

For a closer look at the exact dimensions of the TY-B series die clamp please see the following diagram and table

* Clamps with a dimension greater than Max.h+D are also optionally available.

* Specify T-slot dimensions (A.B.C.D) and clamping height (H) whrn ordering.

* Clamping strokes and ectra strokes are for standard models;custom strokes avaible on request.

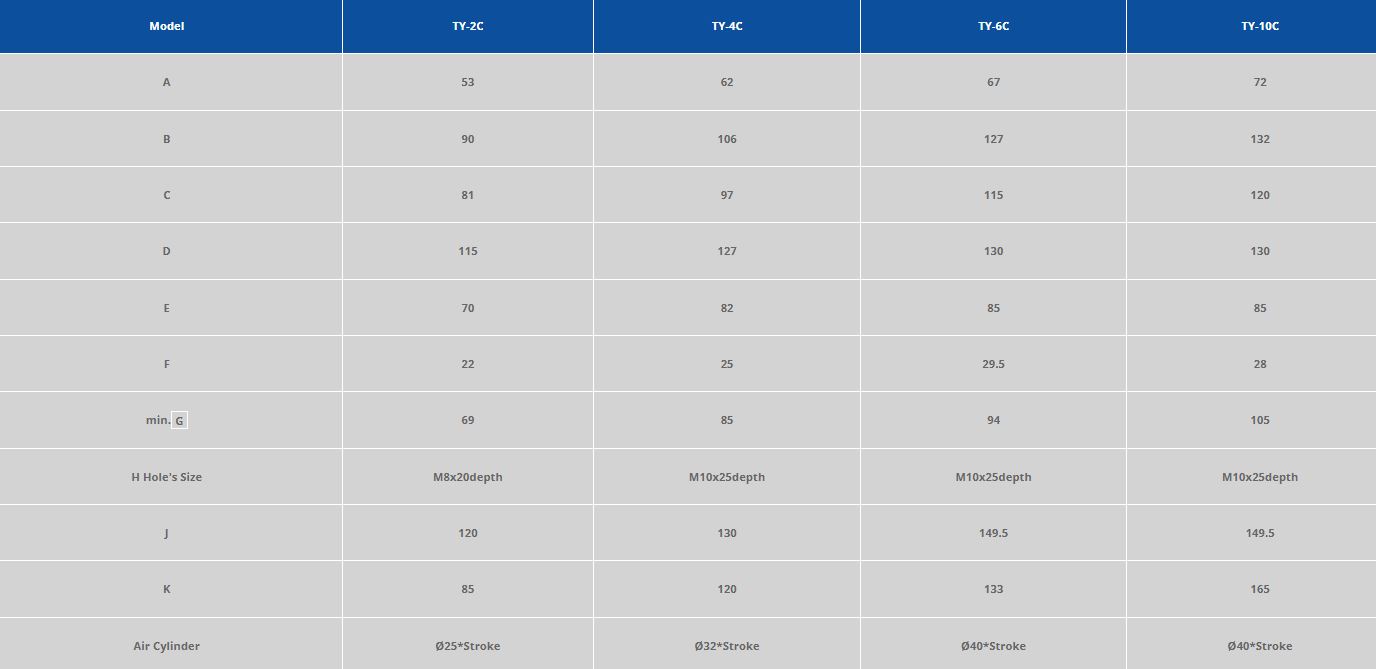

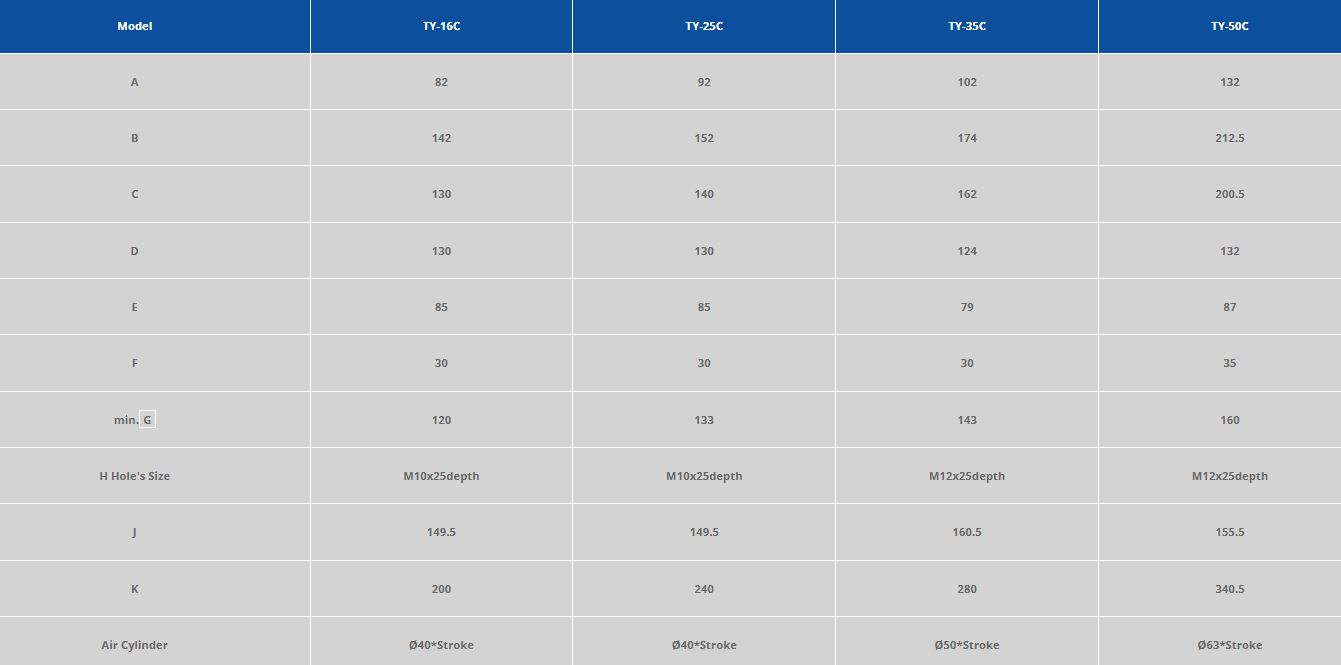

DIE CLAMP TY-C

For a closer look at the exact dimensions of the TY-B series die clamp please see the following diagram and table

* Clamps with a dimension greater than Max.h+D are also optionally available.

* Specify T-slot dimensions (A.B.C.D) and clamping height (H) whrn ordering.

* Clamping strokes and ectra strokes are for standard models;custom strokes avaible on request.

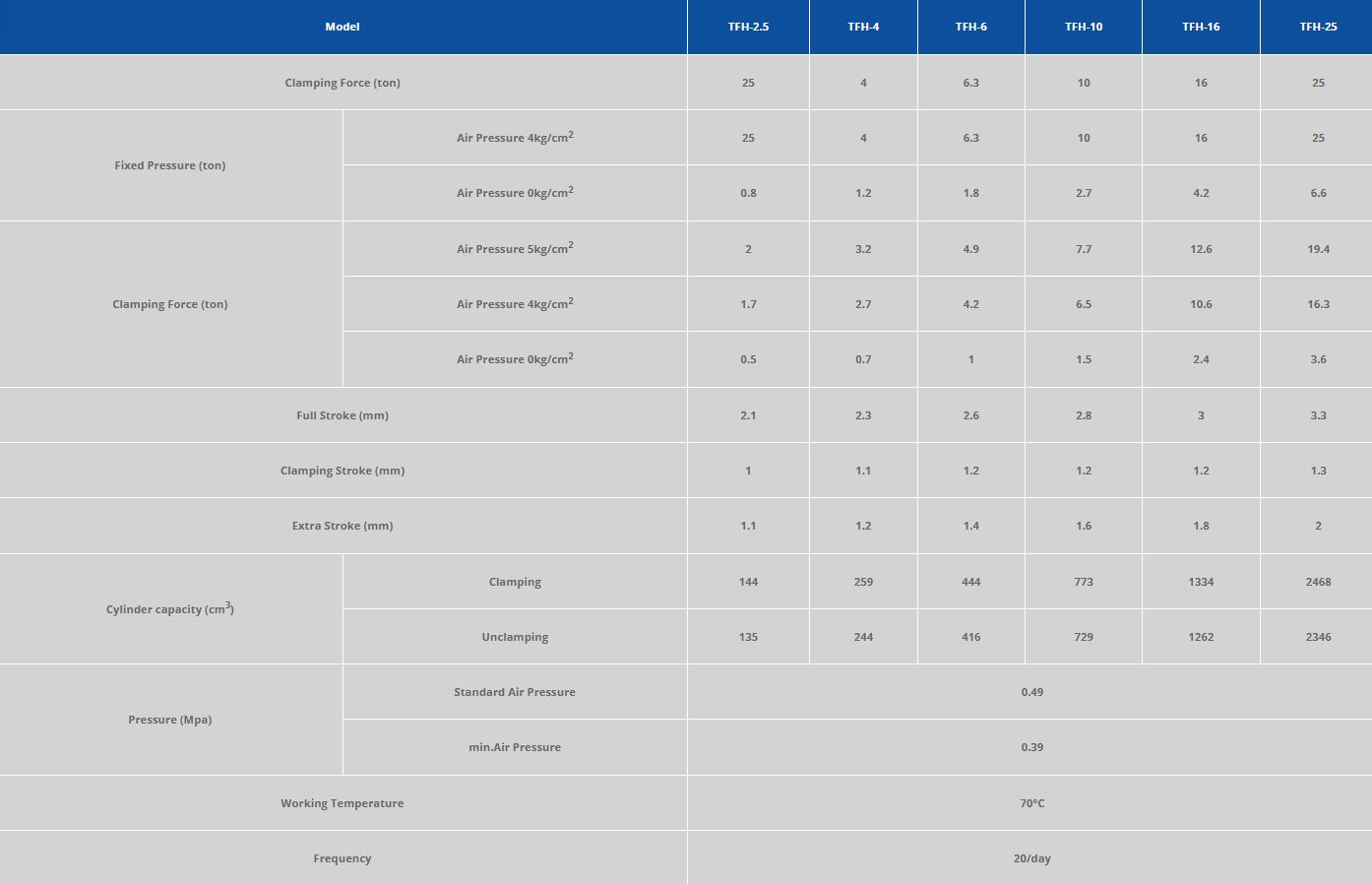

TFH PRESSURE CLAMPS

This pneumatic type clamp is fixed on plate,unified die/mold dimesnsions are required.Mainly used in clean room.

Specifications

Dimensions

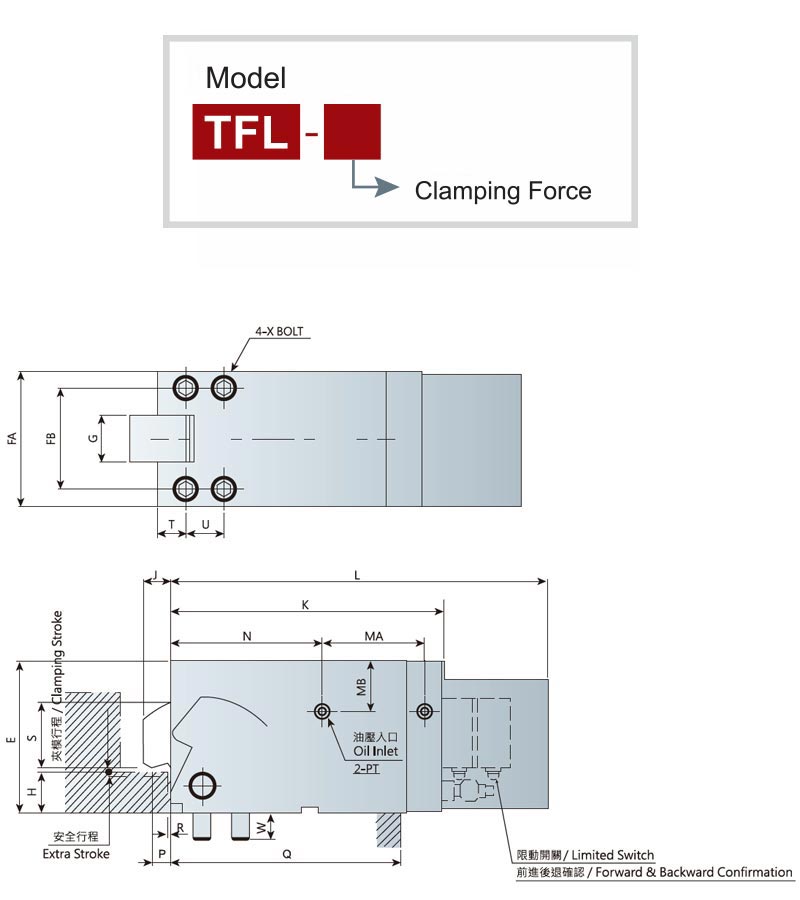

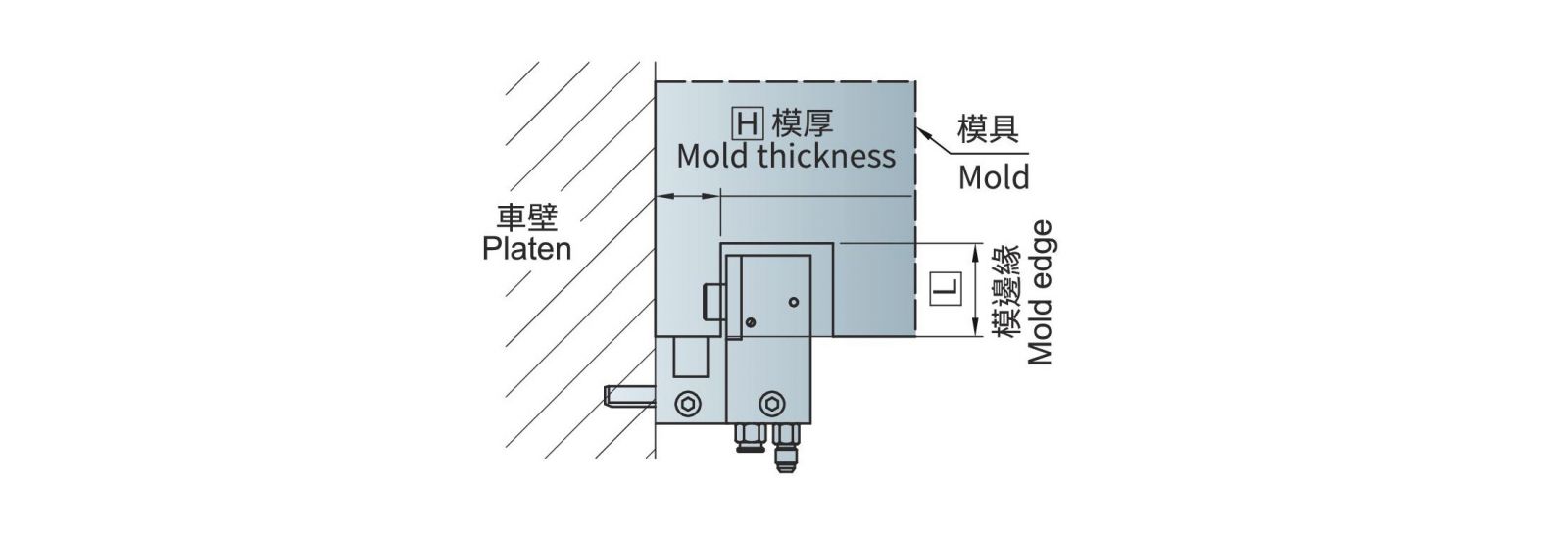

TFL FIXED CLAMP

specification:

Dimensions

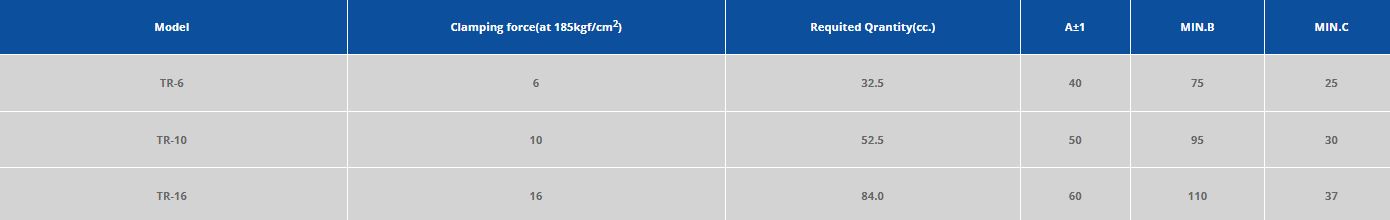

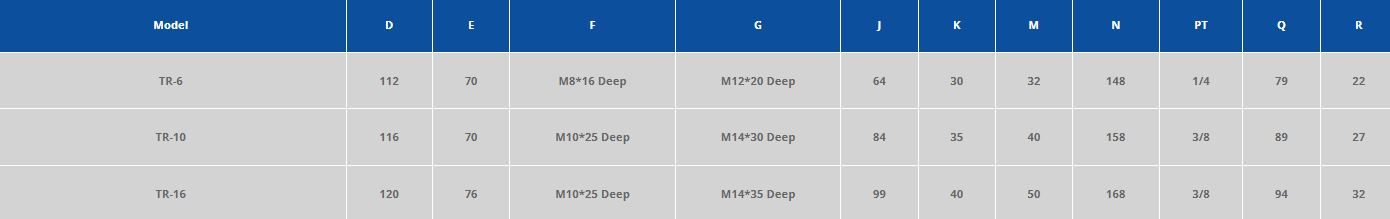

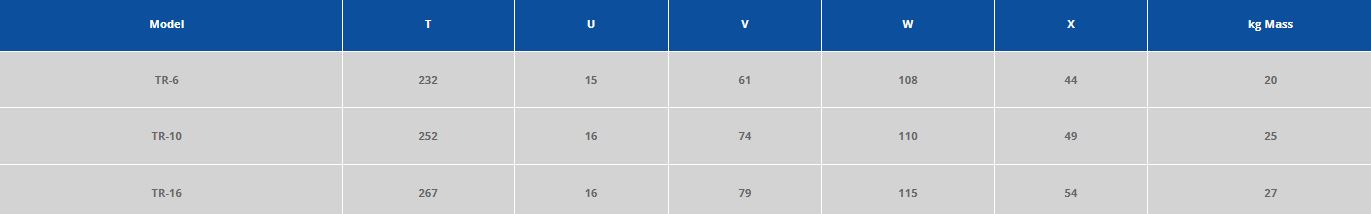

TR ROTATING CLAMP

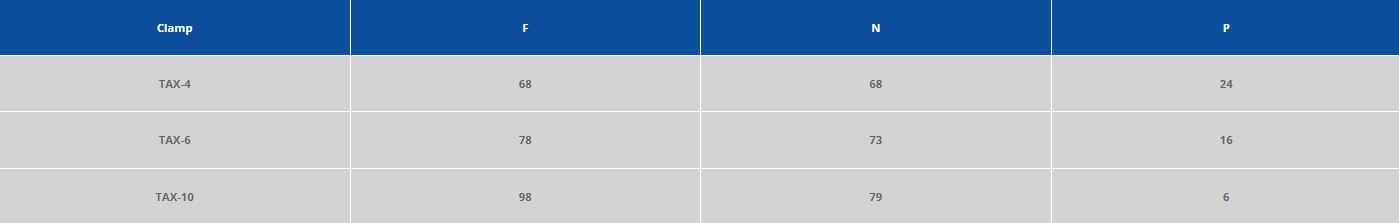

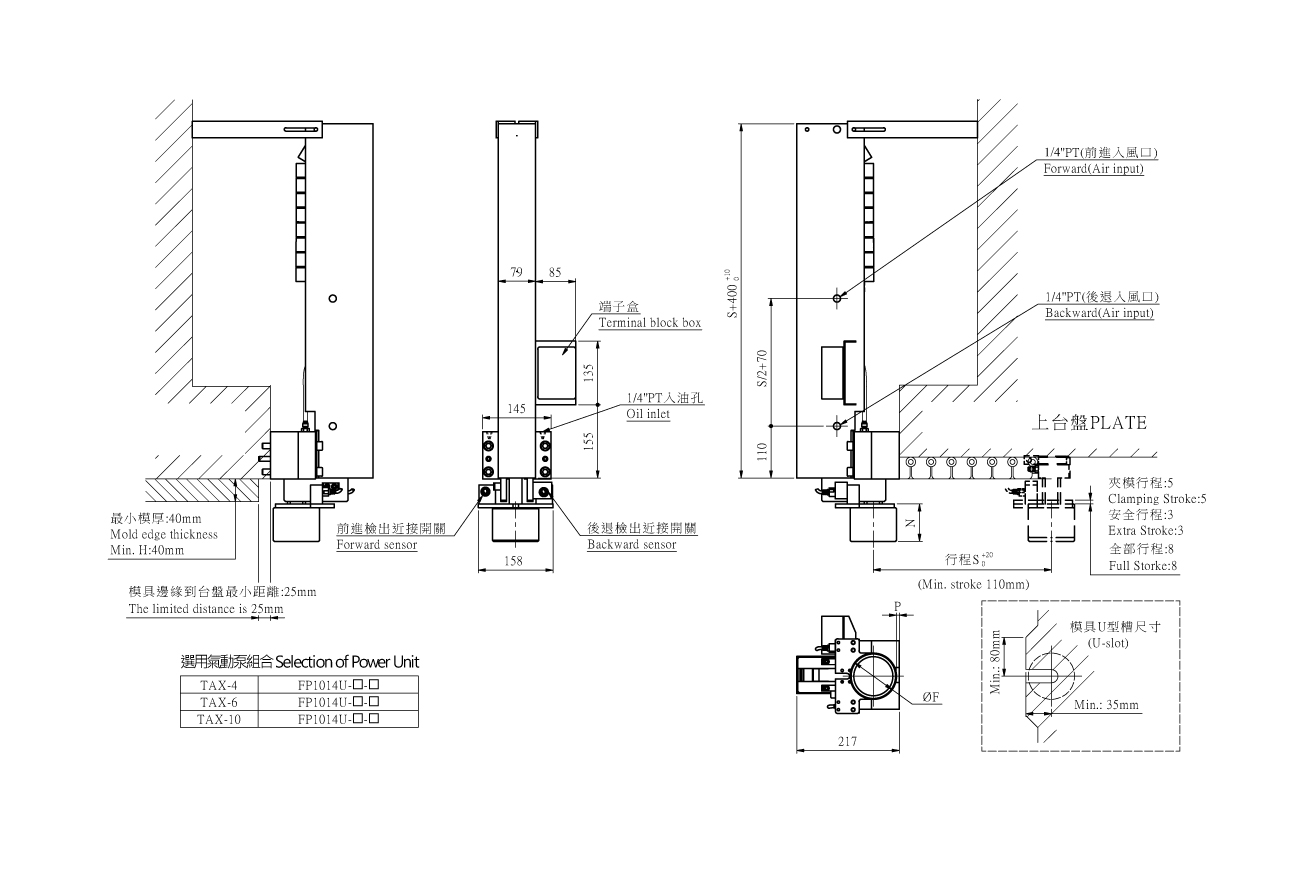

TAX PNEUMATIC CLAMP

This TAX system uses an automatic pneumatic pressure mechanism to individually clamp upper dies.This system is well suited for both smaller and larger hydraulic presses.

Product codes

Diagrams

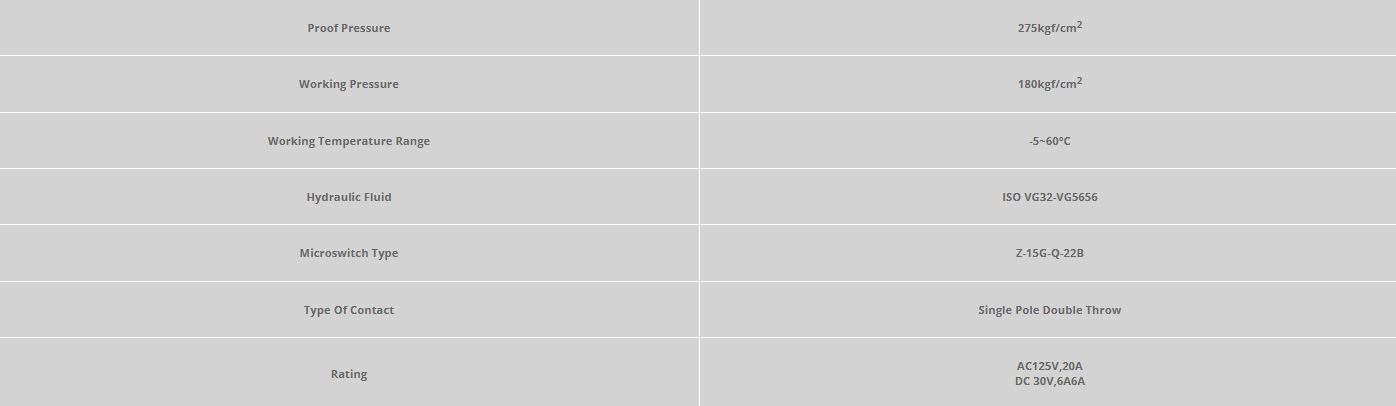

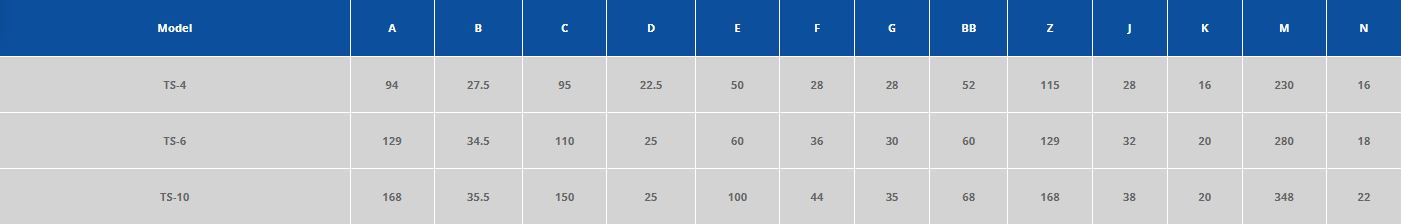

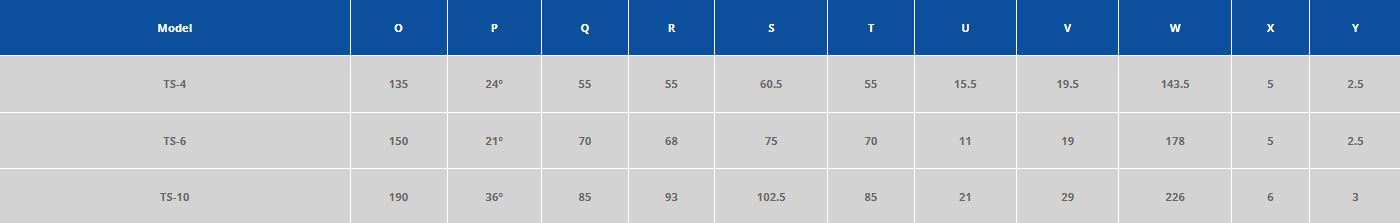

TS SWING TYPE CLAMP

This system is hydraulically controlled and uses a swing motion to lock the dies or plates in place once it is positioned. It offers very secure clamping and is available in three different models.

specification:

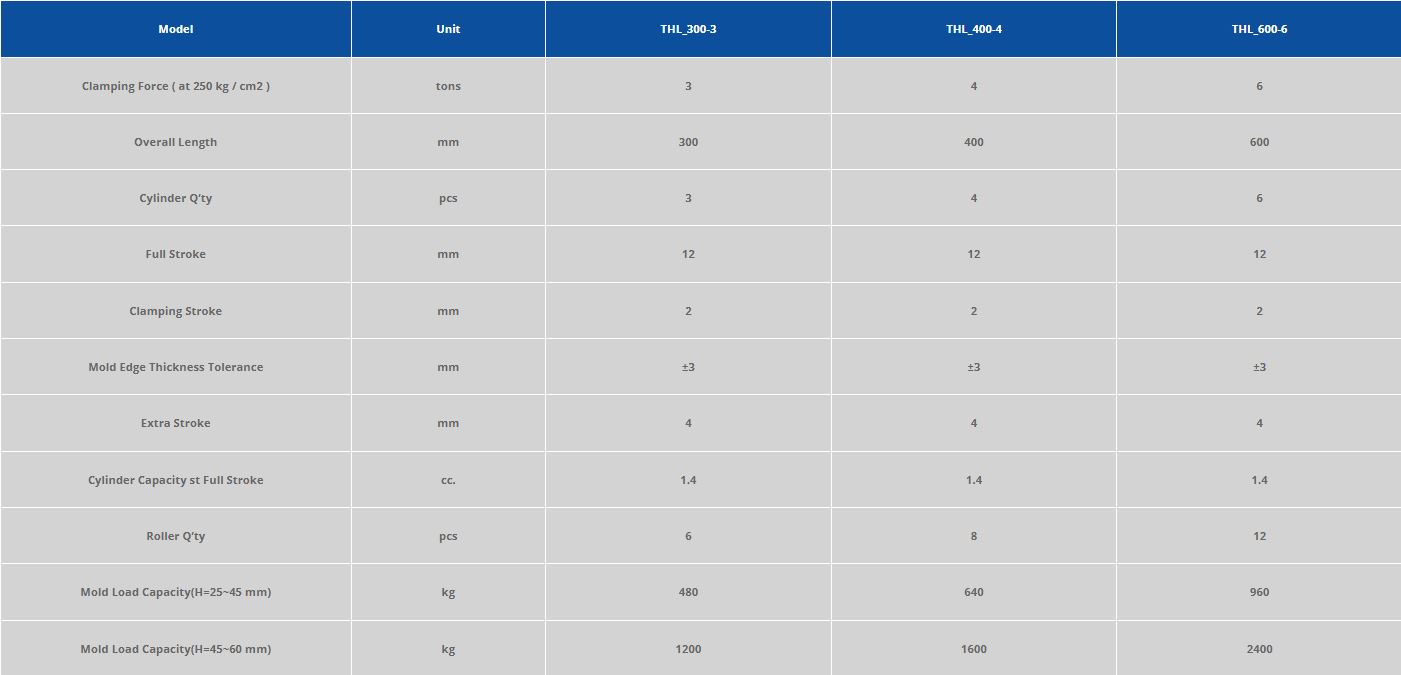

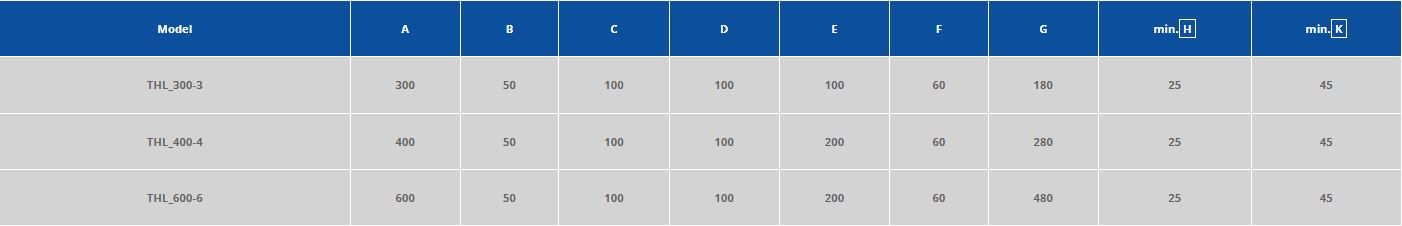

THL DIE CLAMPS

This roller-type clamping device has the function of roller and clamping mold, and it's suitable for middle & small injection molding machines.

specification:

* Mold size should cover on all cylinders to achieve enought clamping force

* Holes setting (D ` E ` F ` G) is adjustable.

* Dimension J varies depending on mold thickness.

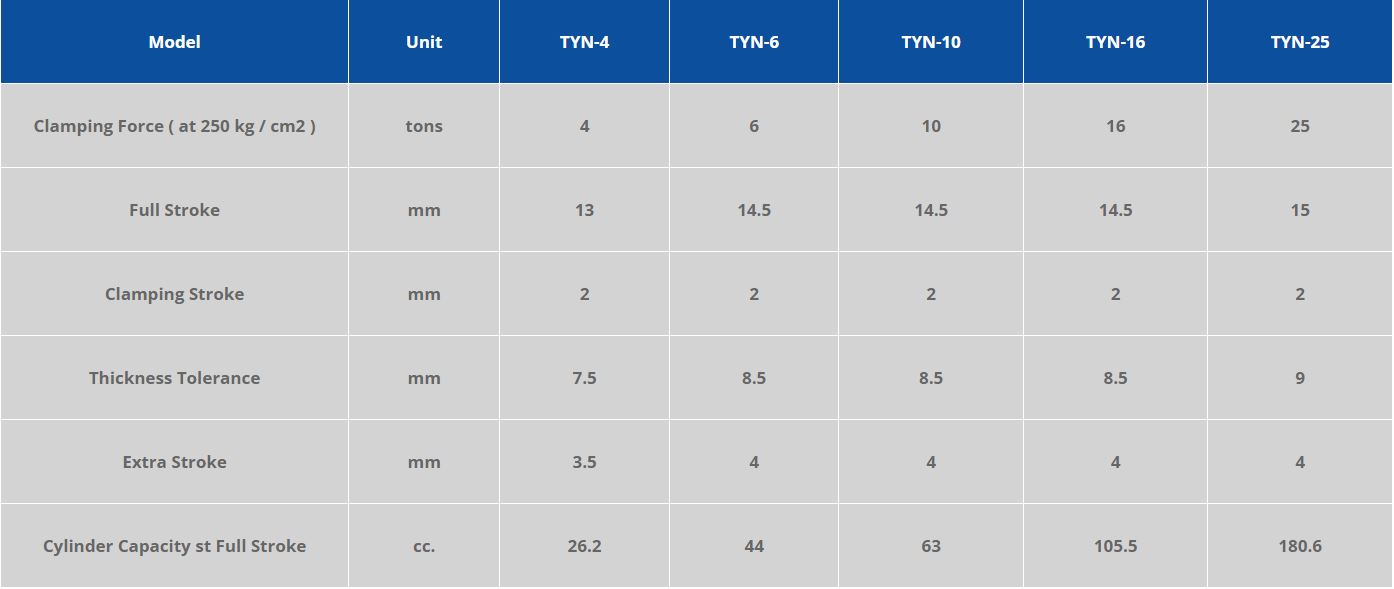

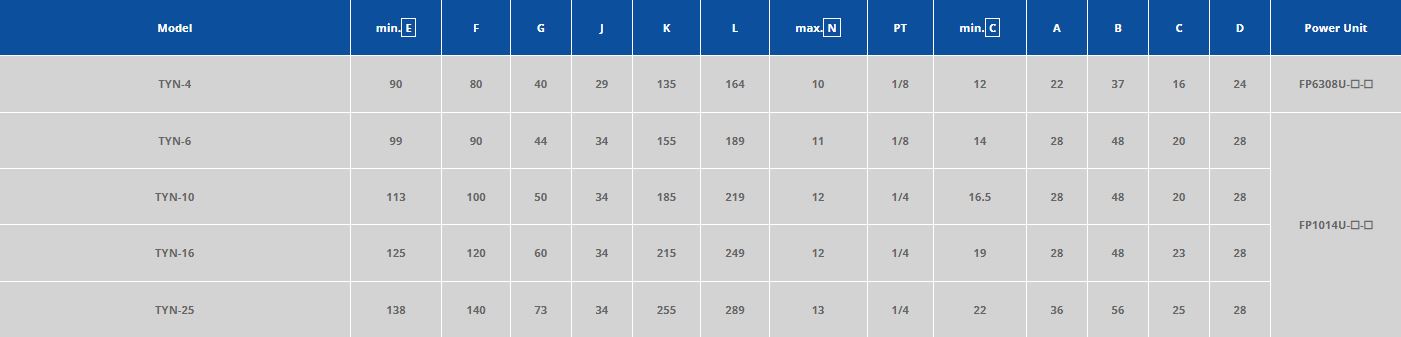

TYN DIE CLAMPS

The characteristics of this double-action clamp are hydraulic pressure keeping,longer stroke,water proof and dirt proof cylinder design. It requires two hydraulic circuits to control clamping and unclamping.The lifetime is much longer.

specification:

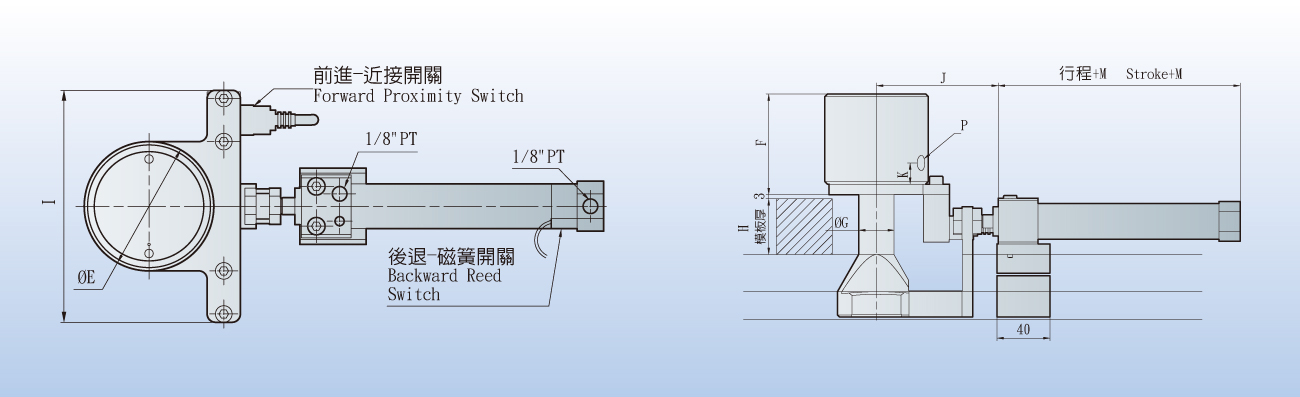

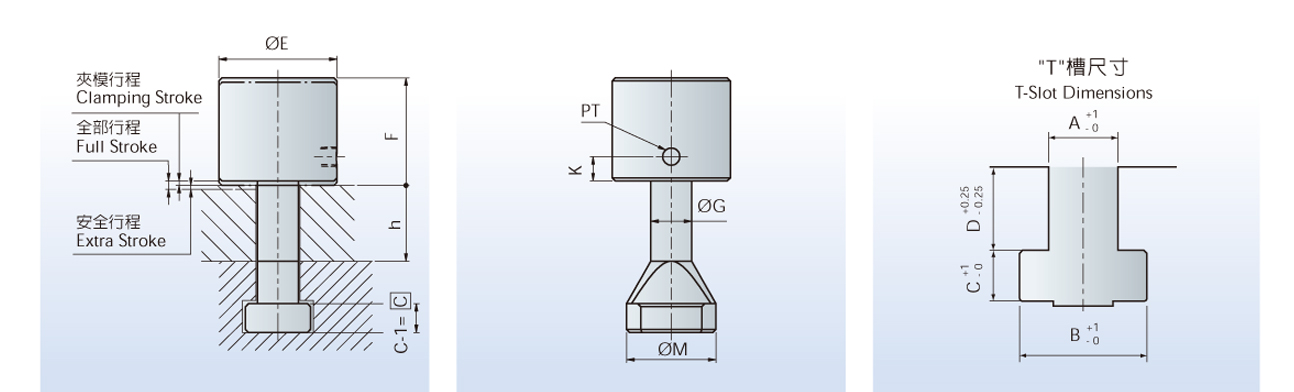

TY-S DIE CLAMPS

This clamp's body can be rotates 360°.

specification: